Hemisphere GNSS provides do-it-yourself installation

Hemisphere GNSS is primarily known for its Outback brand. It includes the Outback Guidance autosteering solution (a smart antenna that combines a GNSS receiver and a GNSS antenna in a single housing), the ESI² electric wheel that steers a tractor, the AC110 application controller that controls the rate and section, and the Rebel terminal in the cab that runs the application software. Hemisphere’s A222 smart antenna is being used by Raven and AgJunction.

“We put these product components together in different configurations for the solutions,” said Miles Ware, the company’s marketing director. “We support hundreds of tractor models with this type of solution or using our terminal for a steer-ready integration, in which you just plug our terminal and steering controller right into the tractor’s interface and it sends the commands to the hydraulic steering.”

One of the challenges with guidance for precision agriculture is that people think that tractors always operate in a wide-open field, where satellite availability is not a problem, Wares explained. That is often not true, however, due to obstructions such as tree canopies.

That is particularly an issue when using real-time kinematic (RTK) corrections for planting and seeding, which require a couple of centimeters of cross-track accuracy. Farmers want to quickly acquire a line and then maintain it. “All those functions are immediately impacted if you have challenges in the positioning solution,” Wares said.

The Outback Guidance brand offers three different packages:

- Atlas Broad-Acre farming for uses that require sub-meter accuracy, such as large seeders or fertilizer sprayers;

- Atlas H10 or the Atlas Row-Crop Service for row crop-level accuracy, for example to plant corn; and

- a sub-inch package that uses RTK technology for automated steering.

One of the key benefits of automated steering is less fatigue for the driver, explained Roland Moelder, Hemisphere GNSS’ product manager for Agriculture Technology. “Especially when it is dark, it is very hard to do a proper job, minimizing the overlap but also not leaving gaps.”

Automated steering also enables farming practices that require more accurate driving than is humanly possible, such as for strip till, the practice of driving on exactly the same lines year after year.

Application-Guided Planting. Hemisphere’s devices can monitor, control and manipulate implements that use ISOBUS standard communications. Operators can select the attributes of their planter in the application; the display will then show them the planter’s location and which sections are active.

For example, if they are approaching a section of the field that they already planted, the AC110 control will turn off some of the seeding heads during the turn.

The same applies to spraying. The product automates the section control and coordinates it with the centimeter-accuracy steering.

Hemisphere’s solution is built around an after-market, so that farmers are not forced to buy the latest and greatest piece of equipment to take advantage of its technology, Wares added. “They can take a lot of their existing equipment, on which they may have already achieved the return on investment or are close to it, and add our solution.”

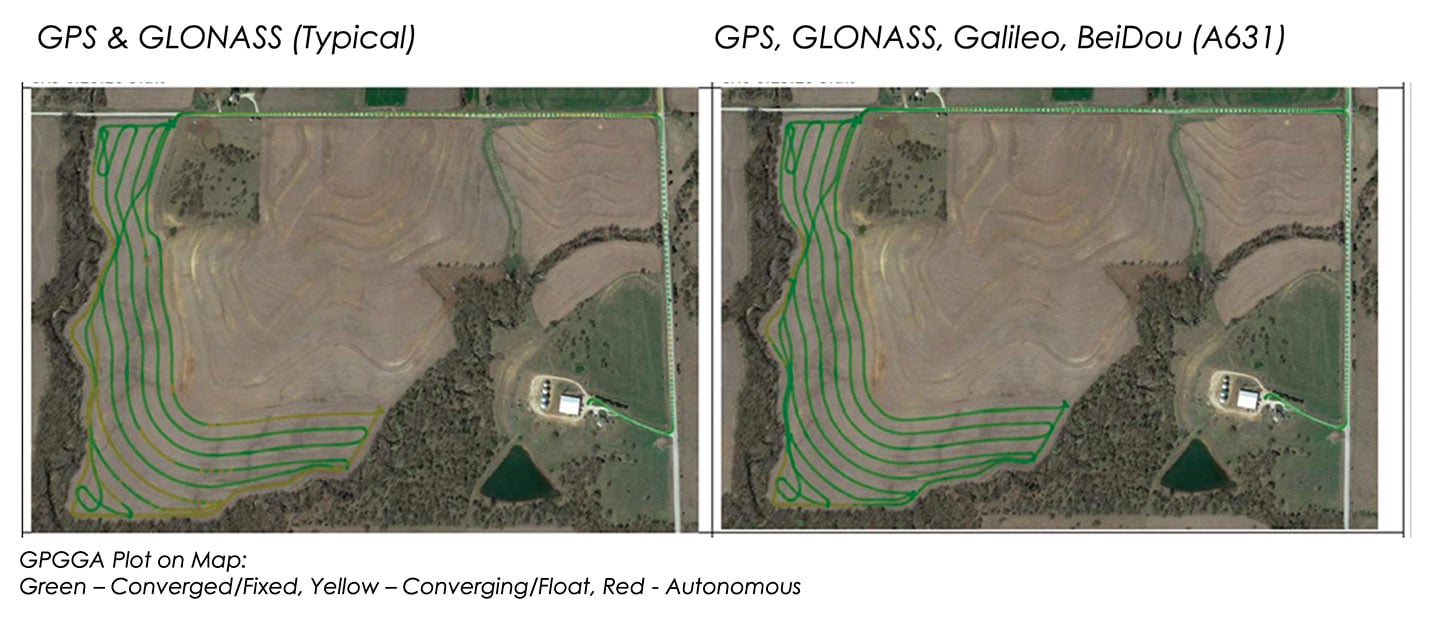

These two plots show how signals from additional GNSS constellations improve mapping. The map on the left is based on only GPS and GLONASS signals, which is typical. The one on the right is improved by adding signals from Galileo and BeiDou. In both images, the green lines are converged/fixed. In the image on the left, the yellow lines are converging/floating. (Images: Hemisphere GNSS)

Do-It-Yourself. To facilitate the installation of its smart antenna, Hemisphere works with all the manufacturers of tractors, sprayers, combines and other field vehicles to make kits that enable customers to perform the installation themselves.

“We take pride in that,” Moelder said, adding that some installations are done by dealers. The ESI2 electric wheel solution is a much easier installation than a hydraulic one. “We also support a list of ‘steer-ready’ vehicle installation kits, which are kits that utilize pre-existing components that are already on the OEM machine, where we just plug-and-play components and make it very easy for the customer to use what is already there.”

Historically, many of these solutions were built around adding hydraulic valves to a tractor, which was a lot of work. “Now, we can communicate directly to the smart valves on steer-ready models,” Wares said, “and it does not require, say, extra hoses, valves and brackets.” Electric wheels, which have tens of thousands of teeth, can manipulate the hydraulics with even finer resolution and are much easier to install than hydraulic valves.

Multi-GNSS technology has a big value for precision agriculture, Moelder said. He cited Hemisphere’s new S631 smart antenna, which tracks all available signals, greatly speeding convergence and maintaining it much better in challenging environments.

Unlike other corrections systems, Hemisphere’s Atlas uses all the available GNSS constellations. “If you are not taking advantage of them, you are really missing out,” said Wares. You cannot take full advantage of a multi-GNSS receiver without multi-GNSS corrections, he pointed out.

Follow Us