Integrating photonic chips for better performance

In June, KVH Industries launched the P-1775 inertial measurement unit (IMU), featuring its new PIC Inside photonic integrated chip (PIC) technology.

After developing and testing the technology for more than three years, the company began incorporating it into existing product lines and has shipped the first units.

The PIC technology features an integrated planar optical chip that replaces individual fiber-optic components to simplify production while maintaining or improving accuracy and performance.

The product is designed to deliver 20 times higher accuracy than less expensive micro-electromechanical systems (MEMS) IMUs. It uses modular designs for ease of integration and has outstanding repeatability unit-to-unit, according to the company.

KVH will add the technology to its inertial sensor product line for use across a broad range of applications, from navigation to stabilization and pointing.

KVH’s fiber-optic gyros (FOGs) and FOG-based products are particularly well-suited for the large and growing autonomous market, which includes applications on land, sea and air, such as drones, people movers, trucks and mining and construction equipment.

Moving Components to the Chip

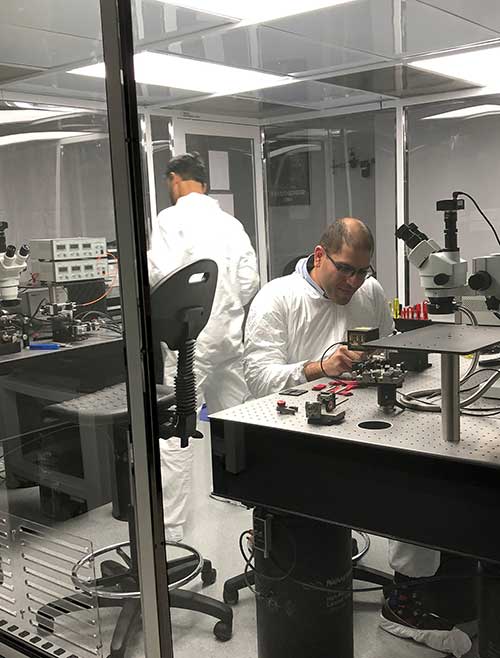

Photo:With PIC technology, KVH’s FOG production process incorporates machine automation for photonics assembly. (Photo: KVH)

The controls on FOGs have an electronics portion and an optics portion. The latter consists of a light source, a detector, couplers, polarizers, a coil (which performs the sensing), and a piezoelectric device for modulating the light, explained Robert Balog, KVH’s chief technology officer.

Until now, the company had fabricated all the products for that optical circuit in its Chicago facility, in a process that was labor-intensive and required much process control. For the PIC, “We’ve taken the couplers and the polarizer sections specifically and moved them onto the chip level,” Balog said.

While KVH manufactures the chip much like any other semiconductor device, rather than passing the light through the fiber KVH is now passing it through wave guides that are contained within that photonics chip, thereby moving the creation of the coupler module into a wafer-level component.

Mass Production and Better Quality

KVH produces the chips en masse on a wafer, then singulates and samples them. Once they are qualified and spot-checked, the chips are incorporated into KVH products.

“This affords us a way to mass produce those components,” Balog said, “and gives us much better quality.”

Additionally, it produces a much smaller device than before. The company will not reveal any numbers regarding its performance improvement until it produces and distributes more PICs, but “it is already producing better results than the manually produced components.”

The production process is intimately linked to the overall performance of the sensor. “The tighter your process control, the more reliable you can make the product,” Balog said.

The new process also improves the device’s field reliability because it contains fewer discreet components. The improved performance specifications on each individual FOG improve the overall performance of the IMU or the inertial navigation system (INS) because the bias is more stable and repeatable.

The Future

What is in the technology’s future?

“The next step is integrating the light source and the detector and potentially a modulator into that chip as well,” Balog said. “So, our ultimate technology road map is to continue condensing what would have been discrete components in traditional gyros all within that chip. As this technology progresses, it will get smaller, tighter, and better. Then you will see big leaps in performance.”

Follow Us